OS GIKEN

Self-locking OS Giken Superlock L1 LSD (188K/L) 28 DISCS <=3.07 RATIO

Self-locking OS Giken Superlock L1 LSD (188K/L) 28 DISCS <=3.07 RATIO

Couldn't load pickup availability

OS Giken Superlock

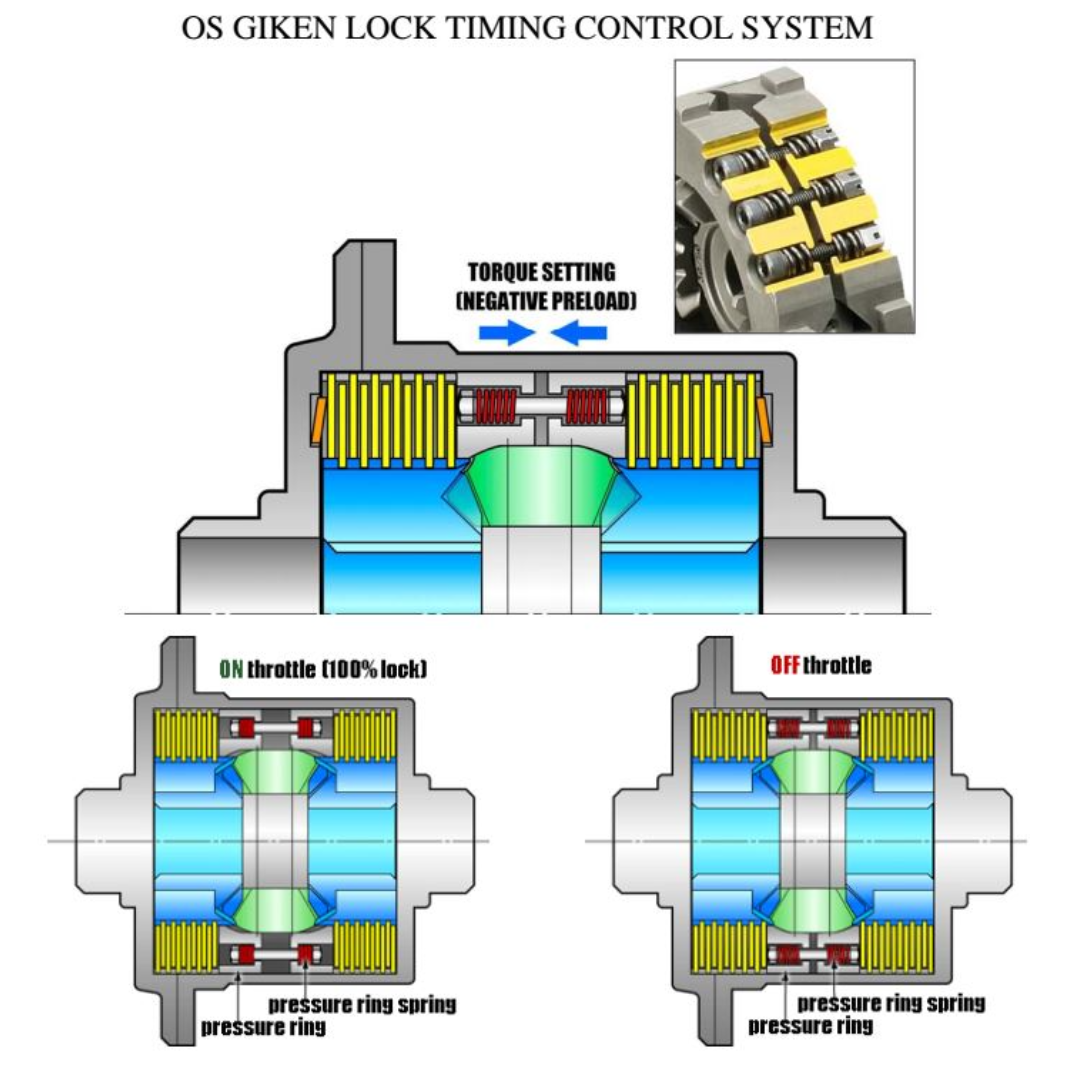

It uses raw forged gears, chemical heat treatment on all components, and high-quality alloy steel. The miniaturized snap ring (Belville washer) allows for increased disc capacity. The herringbone planetary gear design also allows for increased disc capacity as well as increased side gear strength. The patented snap ring (Belville washer) design allows for progressive, adjustable locking. The relief cut in the housing minimizes stress on the cone spring during LSD operation. The friction discs are precision machined on both sides simultaneously, to extremely tight tolerances (only two machines in Japan have this capability).

No break-in required: The OS LSD is precision-machined to extremely high tolerances; once installed, it can be used immediately for racing.

No Service Required : The LSD OS has a true 100% blocking capability and is made from high quality materials using advanced manufacturing methods to ensure extreme durability.

Ultra-consistent performance: The design and construction of the OS LSD prevent significant component wear, ensuring consistent performance regardless of usage. Many teams have been using the same OS LSD for over 10 years without requiring any service, other than routine maintenance (periodic fluid changes).

Fluid changes at standard factory intervals: OS recommends the first fluid change after a single event or between 800 and 1,600 km to remove traces from the manufacturing process. Subsequent fluid changes should be performed at the manufacturer's recommended intervals.

Quiet and controlled for road driving: Because the OS LSD offers smooth, progressive locking up to 100% with a low amount of preload, it behaves like an open differential at low speeds, but still efficiently transfers power to the ground under load.

CONVENTIONAL LSD DIFFERENTIALS HAVE THE FOLLOWING DRAWBACKS WITH RESPECT TO SUPERLOCK

Required break-in procedure : Typically involves performing figure-8s on an empty lot for 30 minutes. Since 100% locking capacity is not possible, the friction generated by the discs produces high levels of heat, which wears the discs down so they can seat properly together. (Lower manufacturing tolerances for the discs result in variations in shape, thickness, etc.) This type of break-in procedure can result in uneven wear between the left and right sides of the LSD.

Required Periodic Service: Since this type of LSD cannot achieve true 100% lockup, the constant friction in the LSD components generates more heat, leading to increased wear or premature failure, necessitating periodic service of the LSD components.

Inconsistent Performance : Since these LSDs already have driver-induced wear during break-in and continue to wear throughout the life of the unit, actual locking performance decreases the more the unit is used.

More frequent fluid changes required : Due to the amount of friction generated in the LSD, additional heat is produced, which causes the differential fluid to deteriorate more quickly. Fluid changes are typically recommended every 8,000–13,000 km for normal use.

Drawback for normal highway driving: This type of LSD can only operate within a certain locking range (e.g., 60% acceleration, 40% deceleration) and can be adjusted by increasing or decreasing the preload. Typically, the preload is set higher to achieve greater locking capacity, but this comes at the cost of the unit locking up at lower speeds. Normal behavior is wheel hopping in turns and generating unwanted noises.

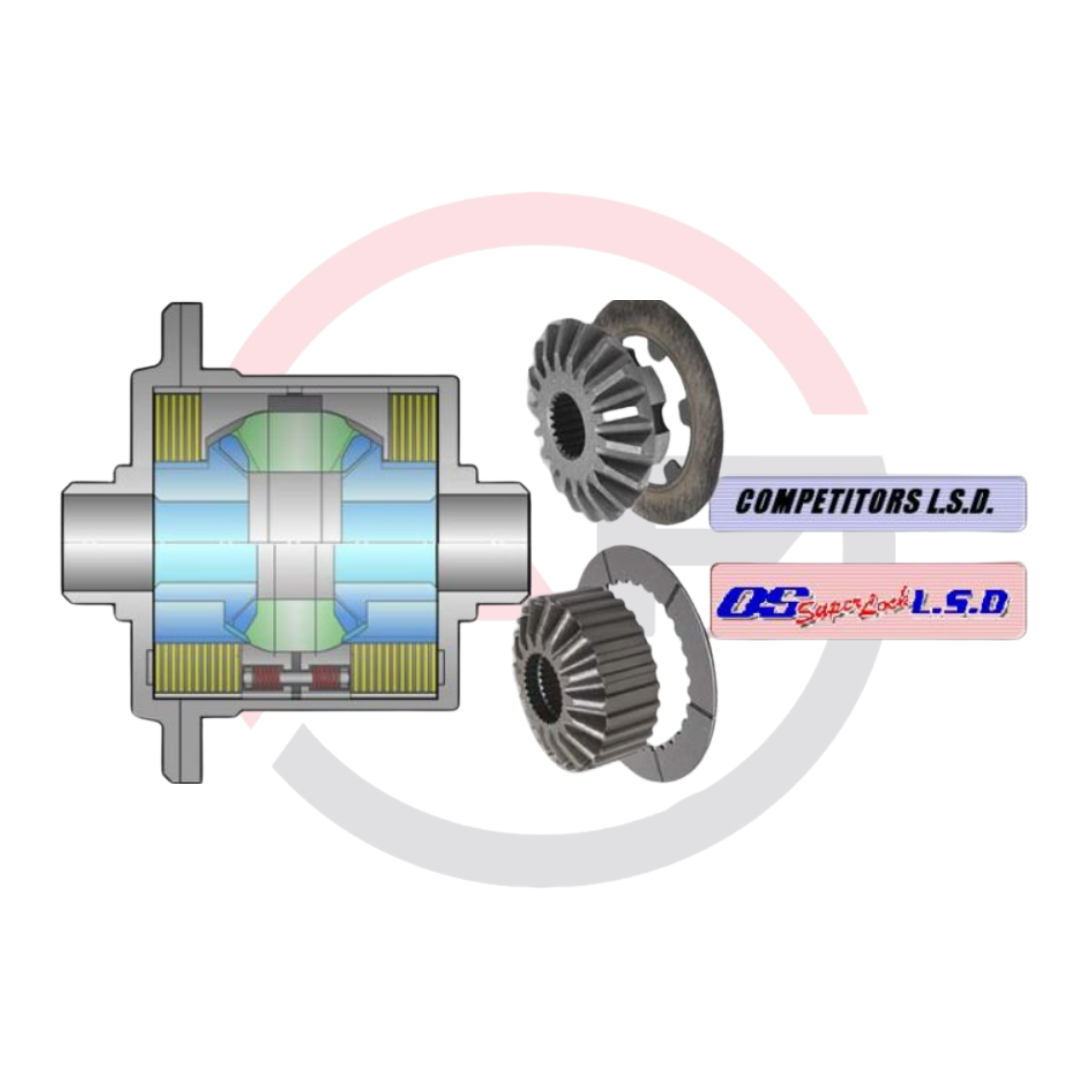

DESIGN DIFFERENCES with "TRADITIONAL" clutch-type LSD

– They usually use cast components, without heat treatment.

– The larger pressure ring limits the space for the discs.

– Less rigid planetary gears.

– Lower disk capacity.

– They do not have progressive blocking capacity.

– Smaller surface area on the discs.

– Discs are usually manufactured with greater manufacturing variability.

– They do not have relief in the housing for the conical springs.

Share